Lyophilization, or freeze-drying, is a preservation technique widely used for pharmaceuticals, particularly biologics, vaccines, and injectable drugs. This process removes water from a product after it is frozen, thereby increasing its shelf life and stability without compromising efficacy.

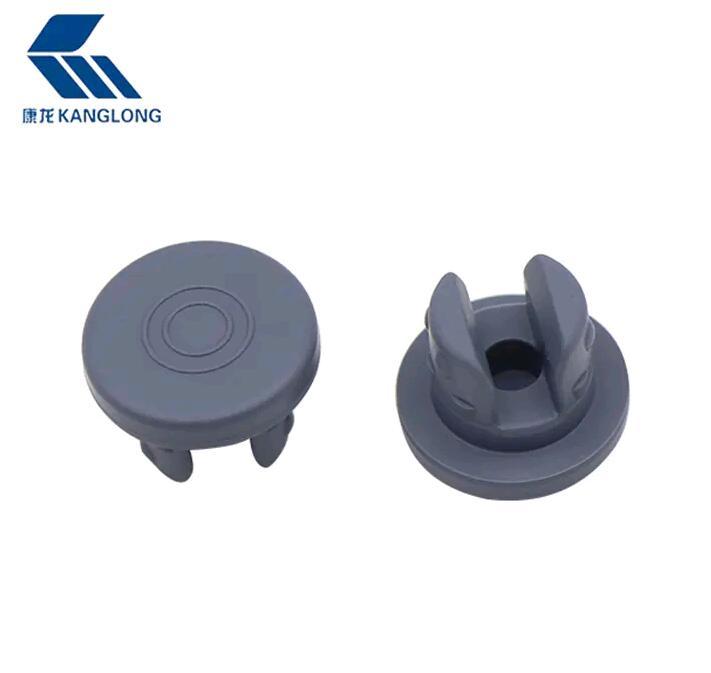

During and after lyophilization, the closure system must maintain a sterile barrier while accommodating changes in vial pressure and volume. Butyl rubber stoppers are commonly chosen due to their excellent sealing properties, chemical resistance, and elasticity, which are critical in preserving the lyophilized product's integrity.

Chemical and Physical Stability

Medical lyophilization freeze-dried butyl rubber stoppers exhibit excellent chemical inertness, ensuring that they do not interact adversely with the drug formulation. Butyl rubber's low permeability to gases and moisture protects sensitive freeze-dried medications from contamination and degradation caused by environmental exposure.

Moreover, the stoppers maintain their physical properties over time, providing a consistent seal throughout the product's shelf life. Their elasticity allows for reliable resealing, which is important during vial punctures for drug reconstitution, helping prevent leaks or contamination.

Enhanced Sterility and Biocompatibility

Sterility is a fundamental requirement for any component contacting parenteral drugs. These butyl rubber stoppers undergo rigorous manufacturing processes that include sterilization by methods such as gamma irradiation or ethylene oxide treatment. This ensures the stoppers meet stringent microbial contamination standards, thereby safeguarding patient safety.

In addition, the materials used in these stoppers are biocompatible and comply with pharmacopeial standards (such as USP <381> and EP guidelines), minimizing risks of adverse reactions when in contact with the drug product.

Customization for Freeze-Drying Applications

Unlike standard rubber stoppers, freeze-dried butyl rubber stoppers are specifically engineered to withstand the unique demands of lyophilization. They often feature enhanced surface finishes and coatings designed to reduce particle generation during stopper puncture and vial filling processes.

https://www.klstopper.com/product/pharmaceutical-rubber-stopper/lyophilization-freezedried-butyl-rubber-stoppers.html

Excellent sealing performance

Replacement of barrier rubber stoppers

Provides special chlorobutyl rubber formula for good compatibility

With pharmaceuticals Special treatment process and the most stringent process control ensure the cleanliness of the rubber stopper

Microbiological testing is to ensure the safety of rubber stoppers